What is a pressure (closed) filter for mechanical cleaning?

A pressure (closed) filter (see figure) is a vertical or horizontal cylindrical tank with spherical bottoms and two hatches. The tank is equipped with a drainage system, a water supply device with several distribution pipes or a funnel, external pipelines and measuring instruments.

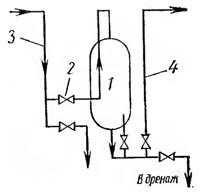

Fig. Pressure mechanical filter

1 – filter; 2 – valve; 3 – raw water pipeline; 4 – purified water pipeline

What is a closed filter filled with?

A closed filter is typically filled with either quartz sand or crushed anthracite with a low sulfur content, or several layers of both filter media, approximately 1 meter thick. A space of approximately 0.5 m is left between the upper bottom of the tank and the filter media, and the working space of the lower spherical bottom is concreted to the level of the drainage system openings.

Where does the water first enter the filter?

First, the water inside the filter, under a pressure of no more than 0.6 MPa (6 kgf/m²), generated by a pump, enters the upper distribution device of the filter. Next, after passing through the filter material layer at a speed of 14-28 mm/s (5-10 m/h), the purified water enters a drainage device with slotted caps with openings 0.4-1 mm wide and exits into the pipeline. Suspended solids (sand, clay, silt) contained in the water are retained on the surface of the filter material or in its pores.

What happens to the filter material during operation?

During operation, the filter material gradually becomes clogged and the resistance of the filter layer increases, resulting in a decrease in its throughput. To restore the filter material’s throughput from accumulated dirt and sludge, it must be cleaned. This is accomplished by backwashing the filter material, which involves passing an intense stream of water at a speed of 20-30 m/h through the contaminated filter in the opposite direction (i.e., from bottom to top) for 8 minutes. This flow loosens and washes away the settled sludge. The water flow rate is then reduced to 6-8 m/h, and the filter material is washed for 15-20 minutes. A complete filter backwash, including all switching operations, typically takes no more than 30-35 minutes. The operating time between backwashes for open filters is 12-16 hours, while for closed filters it’s 18-24 hours. The maximum filter layer resistance can reach 5 m H2O in closed filters and 2.5 m H2O in open filters.

Is it possible to remove various tiny particles from feedwater by filtration?

No, because they carry like electrical charges on their surfaces and thus, by mutually repelling each other, remain suspended. Their sedimentation is possible only after the destruction of these charges, which is achieved through coagulation – the removal of very small impurities from water (an insignificant mass that cannot be settled) by adding coagulants to the water: aluminum sulfate, iron sulfate or iron chloride, as well as other substances that create positively charged particles in the solution.