Optimum water temperature at the boiler inlet

Optimum water temperature at the boiler inlet

One of the most common problems in the operation of steam and hot water boilers is external low-temperature corrosion. This type of corrosion affects metal heating surfaces located in low-temperature zones, such as water economizers and air heaters. Corrosion most often affects areas of the heating surfaces where water or air enters the boiler unit.

External low-temperature corrosion occurs when droplets or a film of moisture form on the heating surfaces, which reacts with the metal surface.

Moisture appears on the heating surfaces during the condensation of water vapor from the flue gases due to the low temperature of the water (air) and the correspondingly low wall temperature.

The dew point temperature at which water vapor condensation occurs depends on the type of fuel burned, its moisture content, the excess air factor, and the partial pressure of water vapor in the combustion products.

Low-temperature corrosion on heating surfaces can be prevented if the surface temperature on the gas side is 5°C higher than the dew point temperature. This dew point temperature corresponds to the condensation temperature of pure water vapor and occurs during fuel combustion.

When fuel (fuel oil) containing sulfur is burned, sulfur dioxide is formed in the combustion products. Some of this gas oxidizes, forming aggressive sulfur dioxide. When dissolved in water, it forms a film of sulfuric acid solution on heating surfaces, dramatically intensifying the corrosion process. The presence of sulfuric acid vapor in combustion products increases the dew point temperature and causes corrosion in areas of the heating surface whose temperature is significantly higher than the dew point temperature. This temperature is 55°C when burning natural gas, and 125–150°C when burning fuel oil.

In steam boiler houses, the temperature of the water entering the economizer usually exceeds the required temperature because the water enters from atmospheric deaerators at a temperature of 102°C.

This issue is more complex for hot water boiler houses, since the temperature of the coolant in the external pipeline of the heating system entering the boilers depends on the outside air temperature.

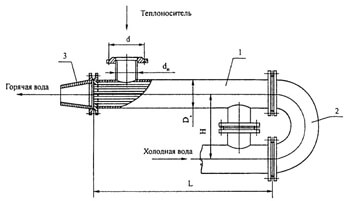

The temperature of the incoming water entering the boiler can be increased by recirculating hot water from the boiler.

The efficiency and reliability of the hot water boiler’s water heating system depends on the coolant flow rate through the recirculation system. As the pump flow rate increases, the temperature of the water entering the boiler increases, as does the exhaust gas temperature, which reduces boiler efficiency. In this case, the energy consumption for driving the recirculation pump increases.

Hot water boiler operating instructions recommend regulating the heating system so that the inlet water temperature does not drop below 60°C when burning natural gas. This requirement reduces their efficiency, as anti-corrosion measures to maintain the heating surface wall temperature can be achieved even if the temperature is below 60°C. However, the heating surface wall temperature must be taken into account in the calculations.

Analysis of these calculations shows that, for example, for hot water boilers operating on natural gas, at a gas temperature of 140°C, the inlet water temperature must be maintained at no less than 40°C, i.e., below the 60°C recommended in the instructions.

Thus, by changing the operating mode of hot water boilers, it is possible to save thermal and electrical energy in the absence of low-temperature corrosion of the metal surfaces of hot water boilers.