Boyko – Boiler units and steam generators – Selection and calculation of dust preparation and burner devices for boiler units

Boyko – Boiler units and steam generators – Selection and calculation of dust preparation and burner devices for boiler units

Over the past many years, significant changes have occurred in the technology of preparing solid fuels for combustion. Large power units operating on solid fuel have been commissioned, while at the same time, there has been a trend toward deteriorating the quality of solid fuel supplied to thermal power plants.

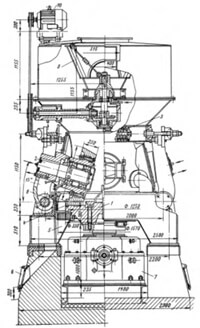

Preparing solid fuel for pulverized combustion involves cleaning it of foreign impurities, pre-crushing, drying, and grinding. Directly related to these processes are the processes of fuel or prepared dust flow from bunkers, as well as fuel dosing into boiler furnaces. The selection of equipment to ensure the efficient and reliable execution of all these processes depends on the key characteristics of the solid fuel: flowability or tendency to stick; moisture content; contamination with solid natural inclusions, as well as metal and wood; resistance to grinding; abrasiveness; and the content of volatile combustible substances, which determine the required depth of fuel grinding.

The use of new pulverized coal preparation elements and systems requires a more detailed coordination of the operating modes of the pulverized coal preparation and combustion equipment. In addition to coordinating the total grinding and drying capacity of the mills and determining the required reserve, it is necessary to consider the ease of control of the pulverized coal preparation systems and burners, as well as the ability to eliminate conditions that lead to reduced efficiency and increased harmful emissions from the boiler unit based on the operating conditions of the milling units.

When operating pulverized coal preparation units, considerable attention is paid to improving reliability. A sound engineering approach to improving the reliability of all components of the fuel preparation system for combustion and bringing the technical utilization rate of the entire unit to the level of the best power plants can improve fuel efficiency and significantly reduce labor and material costs for servicing pulverized coal preparation equipment.

Fundamental aspects of the design of boilers operating on solid organic fuel include the selection of the burner type and their arrangement in the boiler combustion chamber.

The training of qualified thermal power engineers at higher education institutions necessitates mastering the calculation methods for coal grinders and burners in steam boilers.

Students’ project work requires, in addition to regulatory data, the use of recommendations for selecting a number of initial values, the calculation sequence, and explanations during the calculation process. This is the fundamental difference between the student-specific training and methodological guidelines for calculating and designing pulverized coal preparation systems for boiler units and the Regulatory Materials, which contain a strict calculation sequence and the necessary calculation formulas in a concise form.

The main part of these guidelines contains a methodology for selecting and calculating coal grinders and burners for boiler units at medium and high-capacity power plants burning solid organic fuel in a pulverized state. These guidelines are based on the Regulatory Materials for the Calculation and Design of Dust Preparation Units and Burner Devices, developed by a team of authors from leading research institutes and energy companies (VTI, NPO TsKTI, ORGRES, TEP, TKZ, ZiO and BKZ, etc.).

These regulatory materials are aligned with the “Standards for the Technological Design of Power Plants,” the “Rules for the Explosion Safety of Installations for the Preparation and Combustion of Fuel in a Pulverized State,” the “Rules for the Technical Operation of Power Plants,” and the “Regulatory Method for Calculating a Boiler Unit.“

These guidelines provide data for the calculation and design of dust preparation units and burner devices for boiler units up to 1200 MW. The International System of Units (SI) is used.

These guidelines are intended for students majoring in thermal power engineering at energy and technical universities and can also be used by employees of design and engineering organizations.