Table 1.2 lists the main dimensions and characteristics of the PVMR type heat exchangers. The heat exchange surface is manufactured using tubes with a diameter of 16×1 or 19×1 mm (22×1 mm available upon special order) made of brass, stainless steel, or MNZh-5-1 alloy. For an operating pressure of 10 kgf/cm2 (1.0 MPa), the heaters are manufactured with flat bottoms, and for a pressure of 16 kgf/cm2 (1.6 MPa), with elliptical (Fig. 1.4) bottoms 1.5.

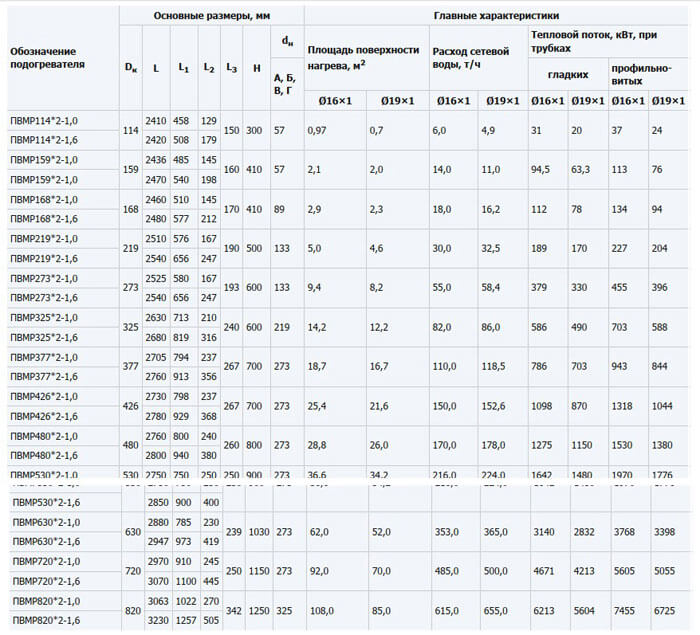

Table 1.2 Main dimensions and characteristics of heat exchangers of the PVMR type

Explanations for Table 1.2: 1. The last digit in the heater designation indicates the medium pressure in MPa. 2. The characteristics are given for heaters with smooth brass tubes measuring Ø16×1 and Ø19×1 mm. 3. The heat flux is determined at the nominal network water flow rate and a 15°C difference in the initial temperatures of the media. 4. The hydraulic resistance of the tube bundle for all heaters with clean smooth tubes is no more than 0.015 MPa. 5.

When using shaped-twisted tubes in a bundle, the heat flux values given in the table increase by 20%, and the hydraulic resistance by 1.5 times. 6. When using flat bottoms, the “L” dimension, depending on the standard size, decreases by approximately 100 to 150 mm. 7. The heat exchange surface is determined by the outside diameter of the tubes. 8. 8. When using stainless steel pipes, heat flow values should be reduced by 8-10%.