PLATE HEAT EXCHANGERS

A characteristic feature of plate heat exchangers is the presence of parallel plates (not counting special plates to prevent channel deformation under external pressure), which form a system of parallel channels. One coolant flows through one channel system, and the other through the other. This type of heat exchanger includes plate-and-frame or plate-and-pack heat exchangers.

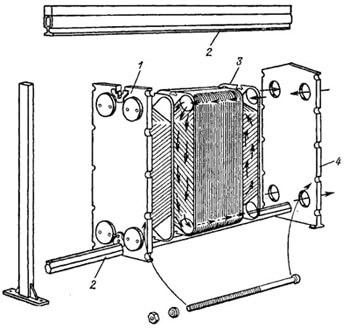

A plate-and-frame heat exchanger is shown in Figure 1.6. It consists of a series of parallel plates held together in a frame, which contains gaskets compressed between the plates to prevent leakage.

Fig. 1.6. Plate-and-frame heat exchanger: 1 — sliding cover; 2 — supporting beam; 3 — plate pack; 4 — fixing cover.

Sealed holes in the plates form channels through which the coolant can flow from the gap between one pair of plates to the gap between the other pair. The flow of each coolant in the space between each pair of plates is also organized. The design ensures that each heat-transfer plate is washed by the heating medium on one side and by the coolant being heated on the other.

The plates are typically 0.5–1 mm thick. Therefore, to withstand operating pressure, they must have multiple points of contact with each other. For this purpose, corrugated metal sheets in a herringbone pattern are most often used. Two such sheets with opposite corrugation orientations are installed on either side of the plate. The points of contact are formed at the intersection of the corrugations. Repeated compression, expansion, and changes in flow direction lead to strong turbulence and, consequently, high heat transfer rates, large pressure drops, and shear stresses. This ultimately helps reduce deposits on the plate surfaces.

Plate heat exchangers are compact and feature a low heat transfer surface area, making them widely used in industries where size and weight constraints are significant. Plates can generally be made of any metal (although mild steel plates are almost never used, as in this case, plate heat exchangers are uncompetitive compared to shell-and-tube heat exchangers). Operating pressures and temperatures are limited to relatively low values due to the seal materials and design features.

Plate heat exchangers are typically used for heat transfer between two fluid streams. Even viscous liquids can be pumped through tortuous passages in turbulent conditions at low Reynolds numbers. Occasionally, plate heat exchangers are used as condensers for moderately dense vapors (such as ammonia) or as evaporators. They have become widespread in the food industry because they can be easily disassembled for cleaning and sterilization.